NON WOVEN BAG MAKING MACHINES

- Details

- Technical Specification

Fully Automatic Non Woven D cut Bag Making Machine JMC- B700

This machine adopts mechanical,electrical optical and pneumatic integration technology, suitable for non woven fabric, different specs of flat bag,D-cut bag,Bottom/Side gusset bag,vest and drawstring bags etc.(used for shopping bag,gift bag,cloth bag) can be made by this machine.

PRICE

Type | JMC – B700 |

Production Speed | 20-120 pcs/min. |

Bag Making Width | 100-800 mm |

Bag Making Lenght | 200-600 mm |

Bag Making Thickness | 18-120 gsm |

Power Supply | 380V/220V |

Total Power | 7 KW |

Overall Dimension (LxWxL) | 7600x1900x2100 mm |

Weight | 3000 kg |

- Details

- Technical Specification

FULLY AUTOMATIC NON WOVEN W CUT CARRY BAG MAKING

MACHINE JMC-500

This Machine is suitable for non woven fabric a fully automatic bag making non woven U cut or W cut bag. The machine with integrated electro mechanical control,using LCD touch screen operation.Machine with stepper method fixed length, photoeletric tracking,computer automatic positioning, computer automatic correction edge, accurate,stable. Machine with automatic counting, can setting counting alarm. Machine with automaitc punching and automatic ironing to make the product with firmly line, beautiful tangent. High efficiency make you more rest assured to using our environmental bag making machine.

TYPE | JMC -500 |

Production Speed | 20-120 pcs/min. |

Bag Making Width | 180-300mm |

Bag making Lenght | 200-600mm |

Bag Making Thickness | 18-120gsm |

Power supply | 380V/200V |

Total Power | 7KW |

Overall Dimension(L*W*H) | 6000x3000x2100 mm |

Weight | 1500 kg |

- Details

- Technical Specification

FULLY AUTOMATIC NON WOVEN BOX BAG MAKING MACHINE JMC-C700

This Machine adopts mehanical, electrical, optical and pneumatic integration technology, suitable for non woven fabric,different specs of flat bag,D- cut bag,botom/side gusset bag,vest bag and drawstring bags etc. can be made by this machine. This machine adopts Taiwan PLC touch screen, which can be edited. Auto counting and stopping when setting number freely. High voltage static processor and auto constant temperature heating controller. Equipped with stepping motor (computer fixed length), manual unwinding magnetic power tension controller and auto rectify deviation, photoelectric tracking, printing color mark track, orientation, auto counting and alarming. Auto punching etc. which make it accurate.

TYPE | JMC-C 700 |

Production Speed | 20-120 pcs/min. |

Bag Making Width | 100-800 mm |

Bag Making Lenght | 200-600mm |

Bag Makinf Thickness | 18-120gsm |

Power Supply | 380V/220V |

Overall Dimension LxWxH | 6000x3000x2100 mm |

Weight | 3500 kg |

- Details

- Technical Specification

FULLY AUTOMATIC NON WOVEN BOX BAG MAKING MACHINE WITH ONLINE LOOP HANDLE JMC-D 700

This machine adopts mechanical,optical and pneumatic integration technology, It’s an advance equipment and has the fuction of automatic handle loop bonding speed up to 75 pcs. Min equal to 5 worker’s bonding speed or 5 handle loop sealing machine suitable for the printing non wove fabric, different specs and shapes of non woven handle bags, flat bags, d- cut bags, bottom side gusset bag, vest bag and drawstring bag etc. can be made by this machine. Which can replace the traditional handle- sealing , reduce labor and manufacturing cost, vest applies to the packing of customs, shoes gifted.

TYPE | JMC-D 700 |

Production Speed | 20-120pcs/min. |

Bag Making Width | 100-800 mm |

Bag Making Length | 200-600 mm |

Bag Making Thickness | 18-120 gsm |

Power Supply | 380V/220V |

Total Power | 12-15 KW |

Overall Dimension LxWxH | 7600x1900x2100 mm |

Weight | 4000-4500 kg |

- Details

- Technical Specification

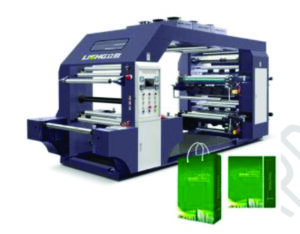

NON WOVEN FLEXO ROLL TO ROLL PRINTING MACHINE JMC-C41200

Model | JMC-C4600 | JMC-C4800 | JMC-C41000 |

Printing Width | 600mm | 800mm | 1000mm |

Printing Length | 180mm-1200mm | 180mm-1200mm | 180mm-1200mm |

Printing Speed | 60m/min. | 60m/min. | 60m/min. |

Plate Thickness | 2.38 mm | 2.38mm | 2.38mm |

Machine Dimension | 4800mmx1600mmx2400mm | 4800mmx1600mmx2400mm | 4800mmx1600mmx2400mm |

- Details

NON WOVEN OFFSET PRINTING MACHINE JMC-16x22

Technical Specification

MODEL | JMC 16x22 |

Max.Paper size | 560x400mm |

Max. Paper size | 150x200 mm |

Max. Printing area | 550x375mm |

Paper Weight | 28-250 gsm |

Printing Speed | 2000-8000 sheets/hrs. |

Plate Size | 560x |

Ink Roller | 16 pieces (3 ink from rollers) |

Total Power | 1.3KW |

Paper Feed mode | Suction cross pull guide |

Moistening mode | Water |

Power Supply | 220V/50Hz |

Package Size(mm) | 1820x1120x1530 |

Total Weight | 850kg |

- Details

- Technical Specification

NON WOVEN FLEXO BAG TO BAG PRINTING MACHINE JMC-870

FEATURES;

Meter counter equipped with pre-alarming bell.

1500-3500/h, steeples governor.

Important PVC Transmission bell,automatic positioning.

Printing roller can be automatically tracing and separating

Oil leaking device can be replaced freely, oil-ink roller and offset can

be seperating harmonized.

Transferring Oil-ink by anilox roller,enhancing polish light for printing,saving oil-ink.

Type | JMC-870 |

Motor Power | 1.5 KW A.C. |

Printing Speed | 1500-3500pcs/H |

Max. Printing Width | 4-5 mm |

Max.Printing Feeding | 1200x640 mm |

Power Supply | 380V/220V |

- Details

- Technical Specification

NON WOVEN AUTOMATIC LOOP HANDLE MACHINE JMC-A700

Production Introduction This new type automatic primary shaping handle ironing machine is developed and improved by our company based of many customer’s feedback.We abandoned rotary cylinder and adopts unique structure, feeding material by stepping motor,precision transmission,combined with man machine interface for parameters setting,which make the machine more intuitive and convenient.Add special shaping device mainly use in the handle ironing of non woven bags.

Type | JMC-A700 |

Handle Loop Length | 380-600 mm |

Bag Material Basic Weight | 40-100/m2 |

Production Speed | 5-20 pcs/min. |

Power Supply | 5Kw |

Overall Dimension | 2100x1200x1500mm |

Weight | 600kg |

- Details

NON WOVEN HYDRAULIC PUNCHING MACHINE

Technical Specification

Model | 625 |

Motor Power | 1.1 KW |

Working Pressure | 10T |

Clamp Travel | 4-75 mm |

Disteance between workable &clamp | 65-150mm |

Weight | 350 KG |

- Details

NON WOVEN ULTRASONIC SEALING MACHINE

Technical Specification

Model | JMC-80 |

Output Power | 2800w |

Working Power Supply | 220V/50Hz |

Working Speed | 0-15m/min. |

Effective Breath | 0-98mm |

Output Frequency | 15KHz |

- Details

NON WOVEN MANUAL LOOP HANDLE MACHINE

Technical Specification

Model | JMC-55 |

Output Power | 2000w |

Working Power Supply | 220V/50Hz |

Working Speed | 0-15m/min. |

Effective Breath | 4-75mm |

Output Frequency | 65-150mm |